The Conceptual Site Model

A conceptual site model (CSM) is the written or illustrative representation of the physical, biological and chemical processes that underpin a site and the processes that control the migration and transportation of contaminants to receptors (contaminant-pathway-receptor pollutant linkages). They are used in conjunction with risk matrixes to consider the magnitude, probability and consequence of contamination occurring (in line with best practice and DEFRA CLR11 guidance).

The in-depth insights acquired from a CSM make them integral to the overall process of ground gas risk assessment, which is why GGS will often use this method to assess the risk of potential harm from ground gas contaminants to receptors for the purpose of giving our clients transparent evidence and expert advice.

CSM in practice

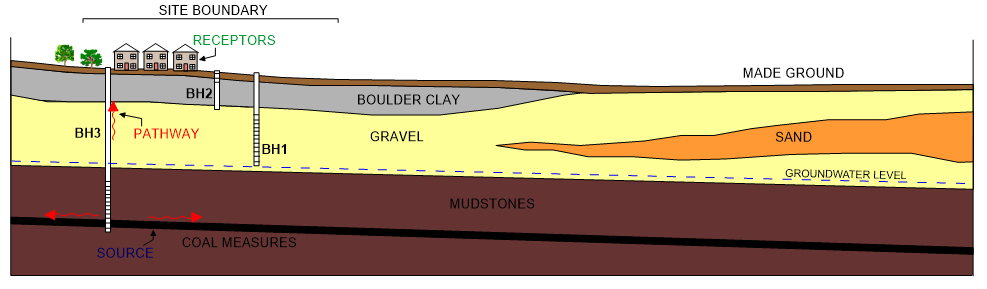

GGS was approached by a client who wanted to understand the risk to their development from coal measures that were identified underlying their site.

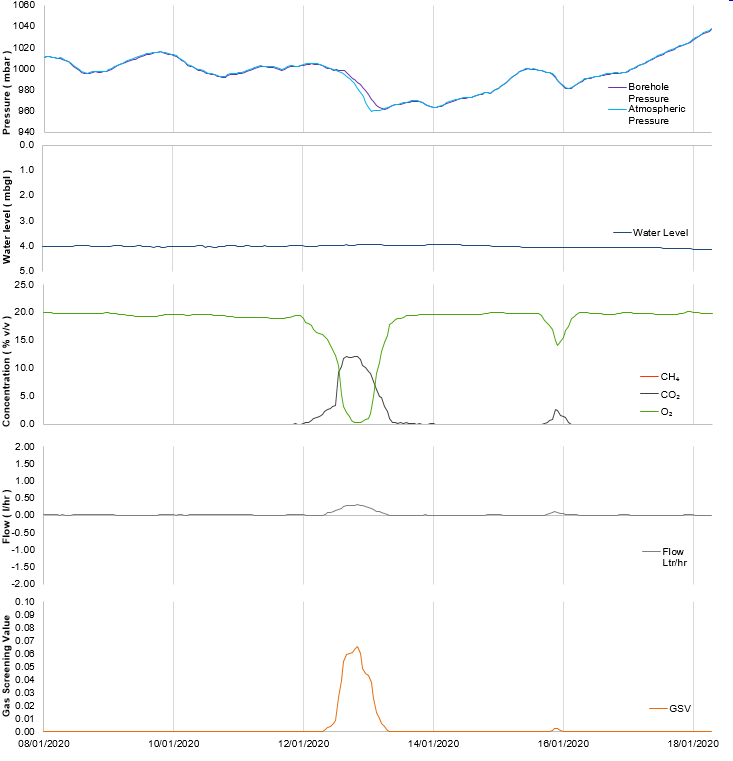

Continuous monitoring confirmed in BH3 a maximum concentration of 12.2% v/v carbon dioxide, a minimum of 0.3% v/v oxygen and a maximum flow of 0.54l/hr (Figure 1). This gave the development a Gas Screening Value (GSV) of 0.066 (Characteristic Situation 1 OR CS1) in line with BS8485:2019.

However, due to carbon dioxide exceeding the 5% threshold and the depleted oxygen, consideration was required to decide whether the development should be accelerated to CS2.

Understanding the CSM

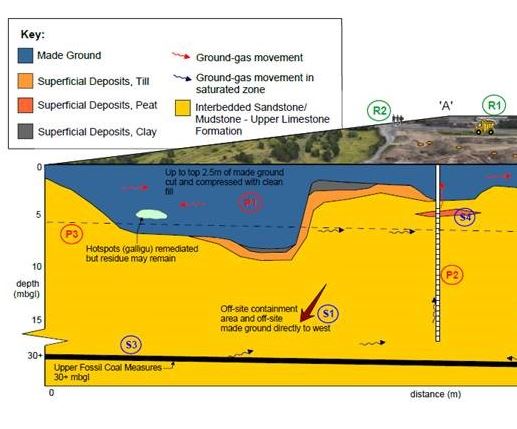

As shown in Figure 2 the site was underlain by a thin layer of made ground (inert materials and gravels), followed by a sequence of boulder clay, gravels and mudstone containing coal measures.

No carbon dioxide thresholds were exceeded within the made ground (BH2) or the gravels (BH1).

The groundwater level remained steady throughout the monitoring period and did not appear to be a ground gas driver.

As shown in Figure 1 the predominant ground gas driver was atmospheric pressure which during a significant pressure fall, drew carbon dioxide into the monitoring well, displacing oxygen on two occasions.

On inspection of the CSM, GGS was able to understand the ground gas pathways underlying the site i.e. the permeable gravels and boreholes. The borehole logs also confirmed a thick layer (2.5m) of low-permeability boulder clay underlying the site below the inert made ground.

Risk assessing the site

From examination of the CSM in combination with the continuous monitoring data, GGS was able to confidently establish the characteristic situation as CS1 rather than CS2 and the risk to the development as ‘very low’.

it was concluded that the worst-case scenario pressure fall produced a maximum carbon dioxide concentration of 12.2% v/v and oxygen depletion to 0.3% v/v. There were no available pathways towards the receptor in the natural strata, except via the monitoring wells, as the site is protected by a thick layer of boulder clay which will inhibit vertical ground gas migration. Therefore, no gas protection measures were required. However, it was recommended that all monitoring wells, particularly deeper wells extending to the gravel and below, were appropriately over-drilled and then grouted in order to remove the potential pathway.

Conclusions

Through conducting a CSM, GGS was able to accurately pinpoint the conditions and risks at the site rather than taking potentially misleading maximum gas readings at face value. This further assessment saved the client ample time and money through proving that expensive corrective measures were not necessary on this occasion. The clear data that informed GGS’s assessment and guidance also allowed them to make informed decisions regarding the safe development of their site, both for construction workers and future occupants.

The following pages include news articles, videos, guidance notes and white papers on a range of ground gas related topics which we hope you will find of interest. Please browse through but if you can’t find something on your particular issue of interest, we’d be very pleased to hear from you so we can put that right.

Establishing a new warehouse involves managing numerous moving parts such as ensuring operational systems are in place, training staff and coordinating logistics. Amidst this complexity, it’s essential to remain compliant with environmental and safety regulations.

One important aspect is managing and mitigating ground gas risk. Keep reading to learn about the process and what to expect.